-

machine de moulage par soufflage de réservoirs ibc

-

Machine de moulage par soufflage à tambour

-

machine de moulage par soufflage de réservoirs d'eau

-

machine de moulage par soufflage de palettes

-

Machine de moulage de kayak

-

Machine de moulage par soufflage de barrière routière

-

Machine de moulage par soufflage flottant

-

Machine de moulage sur mesure

-

Moulé par soufflage

-

Machine auxiliaire

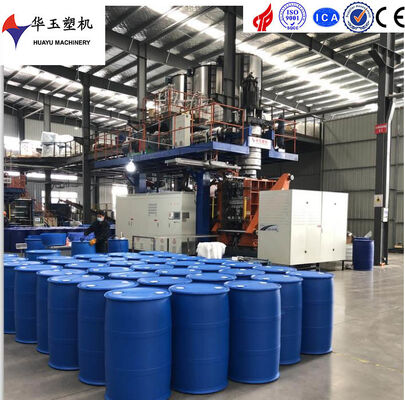

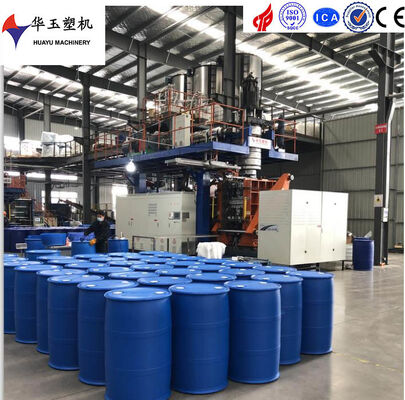

Fabrication de tambours et de conteneurs en plastique tambour soufflage machine de moulage moule plaque taille 1500 1600 haute durabilité pour la production

| Moteur à extrudeuse | 90/90 kW | Application | Fabrication de fûts et de conteneurs en plastique |

|---|---|---|---|

| Matériau de la trémie | Acier inoxydable | moteur à alimentation | 5,5 kW |

| Source d'alimentation | Électrique | Condition | nouveau |

| Consommation moyenne | 280 kW | diamètre de vis | 110/110 mm |

| Mettre en évidence | machine de moulage par soufflage à tambour,machine de fabrication de tambours en plastique,machine de soufflage à haute durabilité |

||

![]()

Description du produit:

La machine de moulage par soufflage de tambour est un équipement industriel de pointe spécialement conçu pour la fabrication de fûts et de conteneurs en plastique avec une grande précision et efficacité.Cette machine est idéale pour la production de gros tambours, en particulier ceux d'un volume de 220 litres, ce qui en fait une solution idéale pour les industries qui ont besoin de conteneurs de stockage en plastique durables et de haute qualité.Utilisation d'une technologie de soufflage de pointe, la machine de moulage par soufflage de tambour assure une qualité de produit constante, une finition de surface excellente et une intégrité structurelle robuste,qui sont essentiels pour les conteneurs utilisés dans divers secteurs tels que le stockage de produits chimiques, la transformation alimentaire et les produits pharmaceutiques.

L'une des caractéristiques les plus remarquables de cette machine de moulage par soufflage à tambour est sa construction robuste et son fonctionnement fiable.qui garantit la durabilité, résistance à la corrosion et entretien facile.L'acier inoxydable est un choix idéal pour une trémie car il empêche la contamination des matières premières et assure une alimentation en douceur pendant le processus de productionCette caractéristique améliore la longévité de la machine et réduit les temps d'arrêt, ce qui en fait un investissement rentable pour les usines de fabrication axées sur la production de fûts et de conteneurs en plastique à grande échelle.

La source d'alimentation de cette machine de soufflage est électrique, ce qui garantit une utilisation efficace de l'énergie et des performances stables tout au long du cycle de production.Avec une consommation moyenne de 280 kW, la machine offre un fonctionnement puissant et constant, lui permettant de gérer des séries de production continues sans compromettre la qualité ou la vitesse.Cette utilisation efficace de l'énergie aide également les fabricants à réduire les coûts d'exploitation tout en maintenant des niveaux de production élevésLa source d'alimentation électrique permet en outre un contrôle précis des fonctions de la machine, contribuant à l'uniformité et à la fiabilité des tambours produits.

Cette machine de moulage par soufflage de tambour est particulièrement adaptée à la production de tambours à anneaux en L, un style populaire de tambour en plastique connu pour sa résistance structurelle améliorée et sa facilité de manipulation.La conception en L offre des bords renforcés qui améliorent la durabilité et la résistance aux chocs, rendant ces fûts très fiables pour le stockage et le transport de liquides et de solides.Les fabricants peuvent produire des machines à tambour à anneaux en L qui répondent aux normes de l'industrie et aux spécifications du client., en veillant à ce que les produits finaux soient à la fois fonctionnels et esthétiques.

En plus de son application spécialisée dans la fabrication de fûts en plastique, cette machine de moulage par soufflage offre une polyvalence et une adaptabilité.Il peut être configuré pour produire différentes formes et tailles de conteneursL'ingénierie de précision de la machine permet des changements rapides de moule et un gaspillage minimal de matériaux.qui améliore l'efficacité de la production et réduit l'impact environnementalLa facilité d'exploitation et d'entretien permet également au personnel d'usine de maîtriser rapidement les fonctions de la machine, ce qui augmente la productivité et réduit le temps de formation.

Dans l'ensemble, la machine de moulage par soufflage est un équipement fiable, efficace et performant conçu pour la production de fûts et de conteneurs en plastique de 220 litres.Sa trémie en acier inoxydable assure une manipulation hygiénique et exempte de contamination, tandis que sa source d'alimentation électrique offre un fonctionnement stable et économe en énergie avec une consommation moyenne de 280 kW.Cette machine de moulage par soufflage aide les fabricants à fournir des produits de qualité qui répondent aux exigences de diverses industriesQue ce soit pour la production à petite ou grande échelle, cette machine se distingue comme un investissement crucial pour les entreprises qui visent à exceller sur le marché de la fabrication de tambours en plastique.

Caractéristiques:

- Nom du produit: Machine de moulage par soufflage de tambour

- Condition: neuve

- Application: Fabrication de fûts et de conteneurs en plastique

- Taille de la plaque de moisissure: 1500*1600

- Matériau de la trémie: acier inoxydable

- Puissance du moteur de l'extrudeuse: 90/90 kW

- Spécialisée dans la production de tambours à double anneau en L

- Machine de moulage par soufflage de tambour à haute efficacité adaptée à différentes tailles de tambour

- Machine de moulage par soufflage durable et fiable à usage industriel

Applications:

La Huayu HYBM-220 Drum Blow Moulding Machine est une solution hautement efficace et durable conçue pour la fabrication de fûts et de conteneurs en plastique.En tant que machine de soufflage de premier ordre originaire de ChineCe modèle est particulièrement adapté à la production de fûts en polyéthylène haute densité (PEPH),ce qui en fait un excellent choix pour les industries nécessitant des conteneurs robustes et résistants aux produits chimiques.

Dans divers scénarios industriels, le HYBM-220 excelle comme machine à tambour à anneaux en L, répondant parfaitement à la demande de tambours à structures en anneaux en L couramment utilisés dans les industries chimique, pharmaceutique,et des secteurs alimentairesSa trémie en acier inoxydable assure une manipulation hygiénique et exempte de contamination, ce qui est essentiel dans la fabrication de fûts utilisés pour le contenu sensible.La capacité de 220 litres de la machine permet aux fabricants de produire efficacement des conteneurs de grande taille, répondant aux exigences diverses des clients.

Avec une consommation d'énergie moyenne de 280 kW et une capacité d'approvisionnement de 40 ensembles par an, le HYBM-220 est optimisé pour des environnements de production continue.Il prend en charge des options d'emballage flexibles selon les besoins du client, garantissant que les fûts sont emballés en toute sécurité pour le transport et le stockage. Le délai de livraison varie de 4 à 5 mois, avec des modalités de paiement disponibles via TT ou L/C,faciliter les processus d'approvisionnement en douceur.

La polyvalence de cette machine à tambour hdpe s'étend à diverses occasions d'application telles que le stockage de produits chimiques, l'emballage de produits agricoles et la gestion des déchets industriels.Sa grande durabilité assure une stabilité opérationnelle à long terme, réduisant les temps d'arrêt et les coûts de maintenance.La machine de soufflage Huayu HYBM-220 offre une solution fiable et rentable.

La quantité minimale de commande n'est qu'un seul ensemble, ce qui permet aux petites et moyennes entreprises d'investir sans coûts initiaux élevés.Dans l'ensemble, le Huayu HYBM-220 est un excellent choix pour les fabricants qui cherchent à améliorer leurs capacités de production de fûts et de conteneurs en plastique de haute qualité,une machine certifiée conforme aux normes internationales.

Personnalisation:

Présentation de la machine de moulage à soufflage de tambour huayu, modèle HYBM-220, une machine à tambour à double anneau de haute performance conçue pour la fabrication de tambours et de conteneurs en plastique avec une efficacité exceptionnelle.Originaire de Chine et certifié CE, ISO9001 et SGS, cette machine à tambour hdpe garantit la qualité et la fiabilité dans chaque cycle de production.

Équipé d'un puissant moteur d'extrudeuse de 90/90 kW et d'une source d'alimentation électrique, le HYBM-220 offre une taille de plaque de moulage de 1500*1600, permettant la production de 20 à 30 pièces par heure.Cette machine de moulage par soufflage de tambour prend en charge des options d'emballage flexibles adaptées aux besoins du client et assure la livraison dans les 4 à 5 mois.

Avec une quantité minimale de commande d'une seule unité et une capacité d'approvisionnement de 40 ensembles par an, la machine huayu HYBM-220 est idéale pour les entreprises à la recherche de solutions personnalisées.Les prix sont négociables., et les modalités de paiement incluent TT ou L/C, offrant une commodité et une flexibilité pour les clients du monde entier.

Assistance et services:

Notre machine de moulage est conçue pour fournir une grande efficacité et précision dans la production de fûts en plastique.nous fournissons un soutien technique complet et des services.

Notre équipe de support technique est disponible pour vous aider avec des conseils d'installation, de formation opérationnelle, de dépannage et de maintenance.Nous offrons des manuels d'utilisation détaillés et des séances de formation pour aider vos opérateurs à comprendre tous les aspects de la fonctionnalité de la machine.

Nous fournissons des inspections régulières, le remplacement de pièces usées et des mises à jour logicielles pour améliorer les performances de la machine.Nos ingénieurs de service sont équipés pour effectuer des réparations et des améliorations sur place si nécessaire.

En cas de problèmes techniques, notre équipe de support peut diagnostiquer à distance les problèmes et vous guider à travers les actions correctives.Nous offrons un service rapide sur place pour minimiser les temps d'arrêt.

Nous fournissons également des options de personnalisation et des conseils techniques pour adapter la machine de moulage par soufflage de tambour à vos besoins de production spécifiques.Notre engagement est de veiller à ce que vos opérations fonctionnent efficacement avec un minimum d' interruptions.